Our laboratories are fully equipped with good production equipment, scientific production process, improved

quality management, and strict inspection systems.

SLA technology achieves single-layer curing through laser scanning exposure. Through the ultraviolet laser beam, according to the designed cross-section of the original layer, solidify point by point, from point to line, from line to surface, through the movement of the lifting table, layer by layer to complete the three-dimensional printing, without mechanical processing or any mold, you can directly Generate parts of any shape from computer graphics data, thereby greatly shortening product development cycles, increasing productivity and reducing production costs.

The main purpose of the dust test is to test the dustproof performance of the fan product casing. Detect the impact of dust intrusion on products, and also detect the impact of dust intrusion on safety and disasters. Safety and disaster effects due to dust include electric shock due to conductive dust, fire or explosion due to combustible dust.

The high and low temperature test detects the aging, fading and deformation of materials, the temperature characteristic test of high and low temperature cycles can perform functions such as high temperature and low temperature cold and heat cycles, and the cold resistance, brittle cracking and deformation of rubber and plastic materials are tested, and long-term storage at low temperature test, operation test of motor products at high temperature.

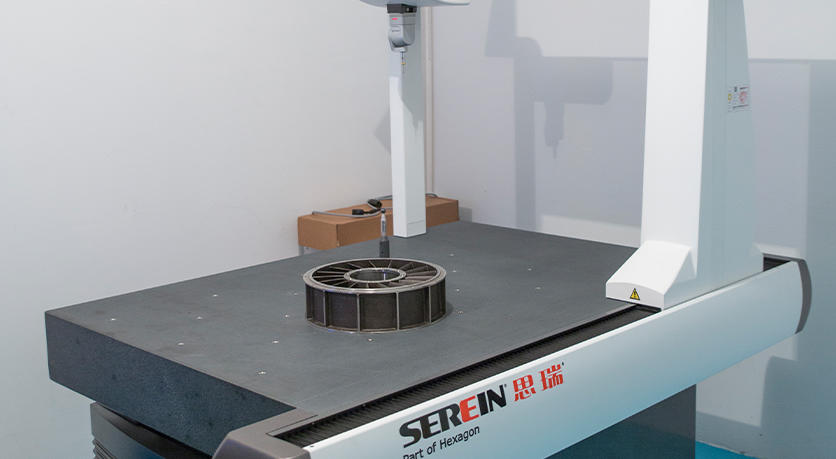

The three-coordinate measuring instrument can accurately capture free-form surfaces through innovative sensors, intelligent algorithms of geometric elements and temperature-selective control connections, which can transmit a large amount of data in a very short period of time. It provides a sufficient guarantee of low wear; high-resolution grating can provide accurate positioning and measurement results; the use of innovative probe technology in it can achieve accurate detection of various arbitrary shapes of objects to be measured or geometric elements.

The company has the first fully automatic fan aging test system in China, through real-time monitoring and testing of all performance parameters of the fan, automatic data collection, real-time point-to-point monitoring and testing, bad alarm and other functions.

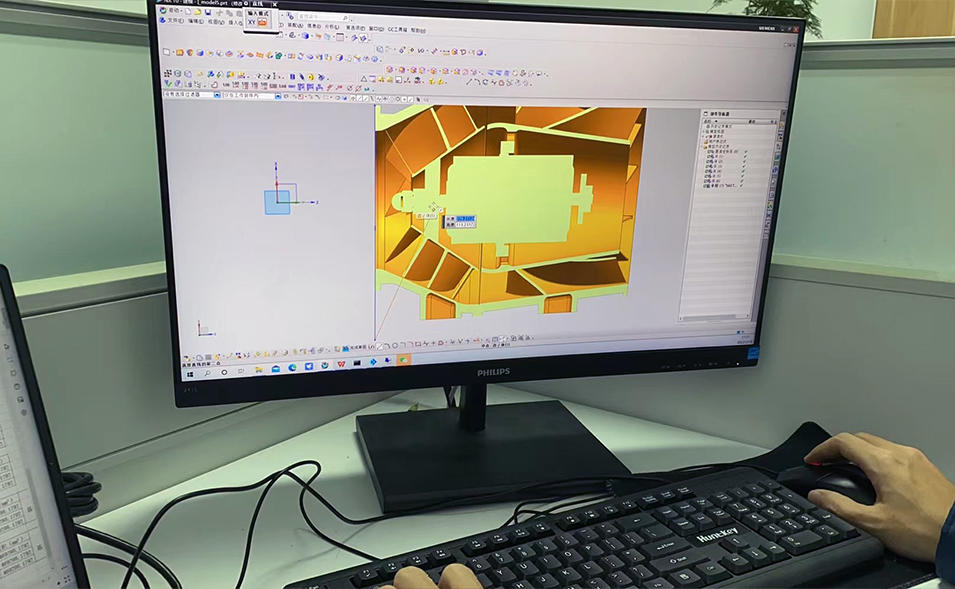

High degree of automation, high production efficiency, strong adaptability, high processing precision and stable quality. The repeatability of the machining quality can stabilize the machining quality and keep the quality of the machined parts consistent.

It has a large-scale CNC lathe with a rotary diameter of 1100mm, which has strong adaptability and flexibility, and can process parts with particularly complex contours or difficult-to-control dimensions.

It has a 3000-6000W large laser cutting machine, which can cut all kinds of metal materials with a maximum cutting thickness of 10mm. It adopts advanced numerical control mode to realize multi-axis linkage and equal-energy cutting that is not affected by the speed of the laser. At the same time, it supports DXP, PLT, CNC, etc. Graphic format and strengthen the interface graphics drawing processing capability; using imported servo motor and transmission guide structure with superior performance to achieve good motion accuracy at high speed.

Manufacturing Execution System (MES) including Supply Chain Management System (SCM) realizes full digital production management of production and manufacturing, correctly grasps the quantity of work-in-progress and the tracking of defective products, and reduces the cost of work-in-progress; uses barcodes to track product serial numbers to improve product after-sales service respond to product quality problems in a timely manner, trace quality history, and improve product governance; greatly reduce on-site manual operations and improve the productivity of on-site management personnel; fully grasp the use of tools and equipment to enable efficient operation of manufacturing resources; enhance statistical reports for enterprise management Decision-making provides real-time, accurate and reliable production data to improve the company's core competitiveness.

Core corporate culture: establish a business with quality; advance technology

Incorporate quality into everyone’s habits

Innovation is the soul of Zhixin, talents are the blood of Zhixin, the team is the body of Zhixin, and quality is the life of Zhixin

Spend some time and money to polish the product better